What is AOI (Automated Optical Inspection)?

AOI is an acronym that stands for Automated Optical Inspection. It is all about automated optical inspection using a camera system. Printed circuit boards (both assembled and unassembled) are non-contact checked for quality using this system.

The Need for Automated Optical Inspection

PCBs play a crucial role in the electrical connection between components such as integrated circuits (ICs) assembled on bare PCBs.

Due to rapid technological advances and the ever-increasing demands we place on electronic devices, modern circuits must be much more complicated than in the past. In addition, the introduction of Surface Mount Technology (SMT) has resulted in printed circuit boards moving toward miniaturization and higher density. Today, even an ordinary circuit board contains a large number of solder joints and layers. The use of increasingly smaller components creates the need to use other verification techniques other than visual verification to ensure that the correct components are applied with the correct polarity and values.

Visual inspection during PCBA production has long been a widely used and accepted method of control. In current times, this method as a stand-alone means of control is now obsolete. The reason is that this method simply cannot guarantee that all possible (internal) problems defects can be detected.

Today's market demands a reliable and fast inspection method. This is why AOI (Automated Optical Inspection) now plays such an important role in the inspection process. With AOI testing, inspection costs are reduced and problems can be detected at an early stage.

The definition of Automated Optical Inspection

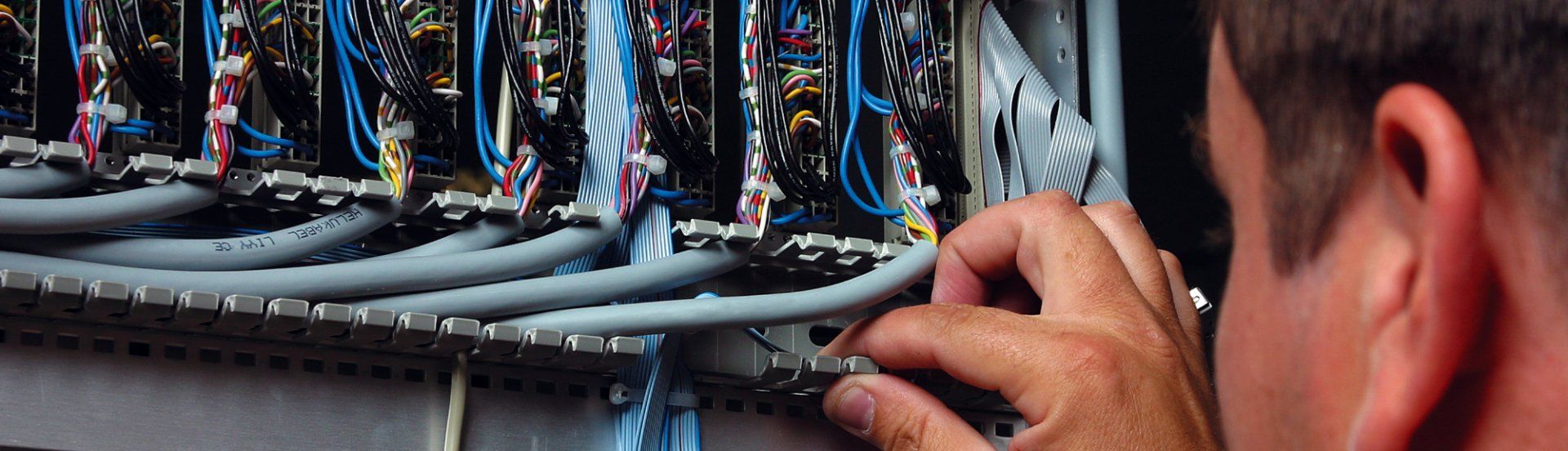

When it talks about Automated Optical Inspection, it refers to an automated visual inspection of manufacturing PCBAs. Depending on the type of device, one or more high-definition cameras will capture images of the PCB surface using light sources, such as LED lighting and infrared or ultraviolet light. A comparison is then made between the captured image and the parameters of the PCB previously entered into the computer. In this way, differences, deviations or even errors can be clearly indicated using the software application provided. This entire process can be continuously monitored by the operator.

The role of AOI in PCB assembly

Automated Optical Inspection is part of a the PCB assembly. It takes place during the manufacturing process. It can be implemented at various stages of the process, such as when the board is still bare, but also during the inspection of the solder paste or during a pre-reflow and post-reflow phase. It is important that any errors are detected as early as possible in the PCB process. AOI is ideally suited for this.

Automated Optical Inspection at Confed

If you are looking for a printed circuit board, feel free to leave the production process to the specialists at Confed. We can provide you with customized advice and can support you throughout the production process. Everything is closely monitored throughout the process, and at Confed we also use Automated Optical Inspection, which you have read about above. If you have any questions about this, you can always contact us and we will be happy to help you.

Choose Confed. Choose fast, reliable and quality.

Got curious?

Have you become curious about what we can do for you in this area? We would like to invite you to contact us. This can easily be done by phone or via our general email address. You can also send us a request via the contact page and we will get back to you as soon as possible.

Contact via:

info@confed.eu or tel: +31(0) 33 454 1340